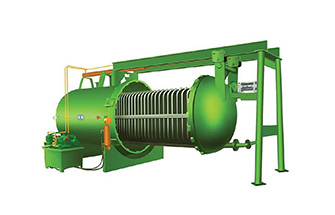

Vertical Leaf Filter

NYB series high-efficiency plate type airtight filter is a kind of high-efficiency, energy-saving, airtight operation precision clarification filter equipment, which is widely used in chemical, grease, petroleum, paint, food, pharmaceutical and other industries.

Share With:

Product Description

NYB series high-efficiency plate type airtight filter is a kind of high-efficiency, energy-saving, airtight operation precision clarification filter equipment, which is widely used in chemical, grease, petroleum, paint, food, pharmaceutical and other industries. The product has unique design structure, small size, high filtration efficiency, high filtrate transparency, good fineness, no material loss, no filter paper, filter cloth or filter element, etc., so the filtration cost is very low, equipment operation, maintenance, easy to clean up.

Working Principle

The main body of the filter is composed of a shell, a filter plate, a cover structure, an automatic slag discharge device, etc. The filter plate is composed of multiple layers of stainless steel filter materials and is installed on the central collecting pipe, which is very convenient for disassembly and cleaning. During filtration, the filtrate containing filter aid enters the filter through the conveying system, so that a stable filter cake is formed on the filter screen, and the filtrate is actually filtered through the micropores of the filter cake layer.

Parameters

|

Model |

Filter area(m2) |

Filter Volume (L) |

Capacity(T/h) |

Working pressure(Mpa) |

Working temperature (℃) |

Weight (kg) |

|||

|

Oil-fat |

Resin |

Beverage |

Rated press |

Max. press |

|||||

|

NYB -2 |

2 |

30 |

0.4-0.6 |

1-1.5 |

1-3 |

0.1-0. 4 |

0.5 |

≤150 |

300 |

|

NYB-4 |

4 |

60 |

0.5-1.2 |

2-3 |

2-5 |

400 |

|||

|

NYB-7 |

7 |

105 |

1-1.8 |

3-6 |

4-7 |

600 |

|||

|

NYB-10 |

10 |

150 |

1.6-3 |

5-8 |

6-9 |

900 |

|||

|

NYB-12 |

12 |

240 |

2-4 |

6-9 |

8-11 |

1100 |

|||

|

NYB-15 |

15 |

300 |

3-5 |

7-12 |

10-13 |

1300 |

|||

|

NYB-20 |

20 |

400 |

4-6 |

9-15 |

12-17 |

1700 |

|||

|

NYB-25 |

25 |

500 |

5-7 |

12-19 |

16-21 |

2000 |

|||

|

NYB-30 |

30 |

600 |

6-8 |

14-23 |

19-25 |

2500 |

|||

|

NYB-36 |

36 |

720 |

7-9 |

16-27 |

23-31 |

3000 |

|||

|

NYB-40 |

40 |

800 |

8-11 |

21-34 |

30-38 |

3200 |

|||

|

NYB-45 |

45 |

900 |

9-13 |

24-39 |

36-44 |

3500 |

|||

|

NYB-52 |

52 |

1040 |

10-15 |

27-45 |

42-51 |

4000 |

|||

|

NYB-60 |

60 |

1200 |

11-17 |

30-52 |

48-60 |

4500 |

|||

|

NYB-70 |

70 |

1400 |

12-19 |

36-60 |

56-68 |

5500 |

|||

|

NYB-80 |

80 |

1600 |

13-21 |

40-68 |

64-78 |

6000 |

|||

|

NYB-90 |

90 |

1800 |

14-23 |

43-72 |

68-82 |

6500 |

|||

Features

1

Fully enclosed filtering, pipeline connection, the product is non-volatile, no leakage, and no environmental pollution.

2

The filter screen is automatically pulled out of the structure for easy observation and cleaning.

3

Double-sided filtration, large filtration area and large residue capacity.

4

Automatically discharge slag by mechanical vibration, open the butterfly valve to discharge slag by vibration, and reduce the labor intensity of workers.

5

Hydraulic control, automatic operation, good filtering effect, low loss.

6

The special stainless steel composite woven screen is used for corrosion resistance, good cleaning and long life.

7

The equipment can be made into a large-capacity, large-area filtration system.

Edible Oil Processing With Dingsheng Machine

Dingsheng Machine is a leading manufacturer specializing in edible oil processing solutions and equipment in China, we provide complete plant solutions for oilseeds pretreatment, solvent extraction, refining and deep processing. More than 20 years’ experience, we are committed to optimizing technology processes, engineer design, project management, installation and training, help customer build the oil mill over the world. When you plan to build an vegetable oil processing plant, please contact us today to get the quote.

Email: company@dingmachinery.com, whatsapp: +86-159 3716 3029.

Email: company@dingmachinery.com, whatsapp: +86-159 3716 3029.

Related Products

-

ZX18A(200-3) Oil PressZX18A (200-3) screw oil press is mainly suitable for one-time pressing of oil crops such as rapeseed, sunflower seed, soybean, cottonseed,peanut,etc .learn MORE

ZX18A(200-3) Oil PressZX18A (200-3) screw oil press is mainly suitable for one-time pressing of oil crops such as rapeseed, sunflower seed, soybean, cottonseed,peanut,etc .learn MORE -

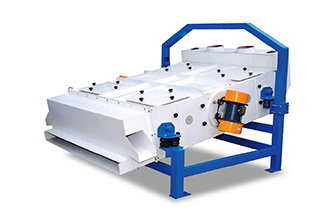

Vibration SieveDingsheng efficient vibration sieve is a more advanced air separation combined screening equipment. It is the most widely used in grain cleaning.learn MORE

Vibration SieveDingsheng efficient vibration sieve is a more advanced air separation combined screening equipment. It is the most widely used in grain cleaning.learn MORE -

Drum Hull SieveDrum hull sieve is a separation and screening equipment, which is mainly used in the pretreatment process of cotton seeds. After the shelling of cottonseeds, the cotton seeds directly enter the machine to separate the kernels and shells.learn MORE

Drum Hull SieveDrum hull sieve is a separation and screening equipment, which is mainly used in the pretreatment process of cotton seeds. After the shelling of cottonseeds, the cotton seeds directly enter the machine to separate the kernels and shells.learn MORE -

Gravity StonerHyde Machinery TQSF gravity grader & destoner is widely used to remove stones by density.learn MORE

Gravity StonerHyde Machinery TQSF gravity grader & destoner is widely used to remove stones by density.learn MORE -

Disc ShellerThe disc shelling machine is suitable for the shelling process of oil materials such as cottonseeds, sunflowers, peanuts, etc.learn MORE

Disc ShellerThe disc shelling machine is suitable for the shelling process of oil materials such as cottonseeds, sunflowers, peanuts, etc.learn MORE -

CrusherThe YPSG series roller crusher adopts two pairs of upper and lower toothed rollers for granular materials.learn MORE

CrusherThe YPSG series roller crusher adopts two pairs of upper and lower toothed rollers for granular materials.learn MORE -

Flaking RollThe YYPYFP type flaking roll designed and developed by our company has uniform crushing, stable operation, small supporting power and high production efficiency.learn MORE

Flaking RollThe YYPYFP type flaking roll designed and developed by our company has uniform crushing, stable operation, small supporting power and high production efficiency.learn MORE -

Steam CookerSteam cooker is one of the main equipment for cooking oil processing. It is mainly used for steaming and cooking of vegetable oil flakes.learn MORE

Steam CookerSteam cooker is one of the main equipment for cooking oil processing. It is mainly used for steaming and cooking of vegetable oil flakes.learn MORE -

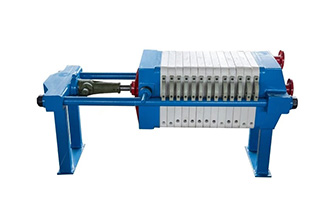

Plate And Frame FilterThe plate frame filter is used for the separation of solid and liquid. Compared with other solid-liquid separation equipment, the cake filtered by the filter press has a higher solid content and an excellent separation effect.learn MORE

Plate And Frame FilterThe plate frame filter is used for the separation of solid and liquid. Compared with other solid-liquid separation equipment, the cake filtered by the filter press has a higher solid content and an excellent separation effect.learn MORE -

Horizontal Leaf FilterWYB series horizontal leaf filter is a precision clarification equipment with high efficiency, energy saving and automatic airtight filtration. The filter leaf adopt a special stainless steel filter screen, which has long life, large output and high precision;learn MORE

Horizontal Leaf FilterWYB series horizontal leaf filter is a precision clarification equipment with high efficiency, energy saving and automatic airtight filtration. The filter leaf adopt a special stainless steel filter screen, which has long life, large output and high precision;learn MORE