Corn Germ Oil Winterizing Equipment

Corn germ oil contains a small amount of wax, which will be precipitated as cotton wool at 25°C, which can easily affect its perception. Moreover, the corn oil that has not undergone dewaxing will feel a peculiar smell when eating, a taste of raw corn, which is also a factor that causes the low quality of corn germ oil.

Share With:

Product Description

Corn germ oil contains a small amount of wax, which will be precipitated as cotton wool at 25°C, which can easily affect its perception. Moreover, the corn oil that has not undergone dewaxing will feel a peculiar smell when eating, a taste of raw corn, which is also a factor that causes the low quality of corn germ oil. The oil content of corn germ oil is not high. With the previous dewaxing method, the crystal formation is small and it is difficult to grow up. Not only does it consume more energy, but the dewaxing efficiency is not high. At the same time, there is more neutral oil in the filtered wax paste, the oil loss is too large, and there is turbidity after long-term storage, which is not conducive to small product packaging.

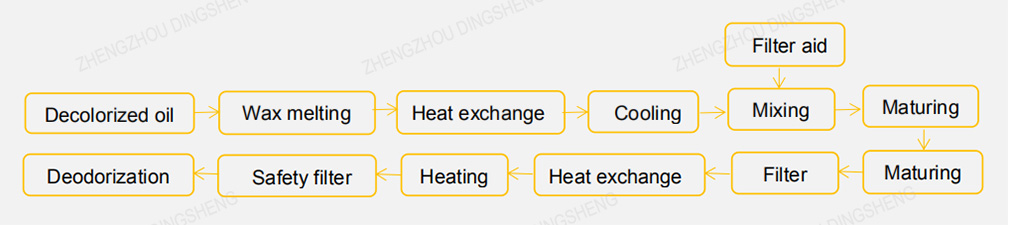

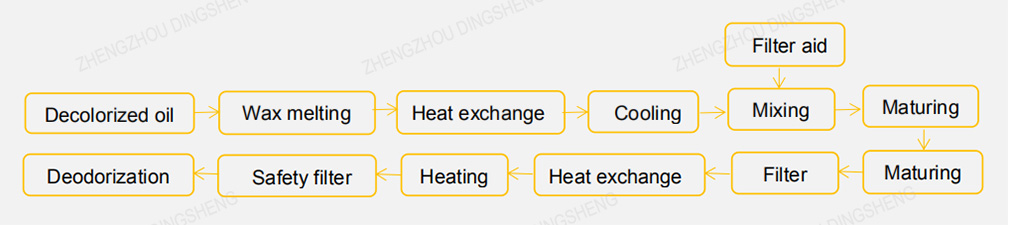

After fully researching and reasonably absorbing domestic and foreign cash technologies, and carefully designing the entire process flow and all supporting equipment, we have developed a complete set of rapid cooling crystallization and crystal growth dewaxing process and equipment:

Decolorized oil or dewaxed filtered turbid oil is heat exchanged with dewaxing cold oil after melting wax, and then quickly cooled in a rapid crystallizer with a cold carrier to make the wax in the oil agglomerate and crystallize, and then add a certain amount of filter aid the oil can be filtered after a period of crystallization and maturation. The filter adopts a horizontal leaf filter, hydraulic control, automatic operation, and good filtering effect. The filtered turbid oil is sent to the wax melter, and the clear oil is filtered and the dewaxing is cold. After the oil is exchanged with the hot oil with dewaxing to recover the cold energy, the oil temperature is adjusted to a certain temperature, and finally enters the safety filter to remove the missing filter aid and other solid impurities, and then enter the next process-deodorization.

After fully researching and reasonably absorbing domestic and foreign cash technologies, and carefully designing the entire process flow and all supporting equipment, we have developed a complete set of rapid cooling crystallization and crystal growth dewaxing process and equipment:

Decolorized oil or dewaxed filtered turbid oil is heat exchanged with dewaxing cold oil after melting wax, and then quickly cooled in a rapid crystallizer with a cold carrier to make the wax in the oil agglomerate and crystallize, and then add a certain amount of filter aid the oil can be filtered after a period of crystallization and maturation. The filter adopts a horizontal leaf filter, hydraulic control, automatic operation, and good filtering effect. The filtered turbid oil is sent to the wax melter, and the clear oil is filtered and the dewaxing is cold. After the oil is exchanged with the hot oil with dewaxing to recover the cold energy, the oil temperature is adjusted to a certain temperature, and finally enters the safety filter to remove the missing filter aid and other solid impurities, and then enter the next process-deodorization.

Edible Oil Processing With Dingsheng Machine

Dingsheng Machine is a leading manufacturer specializing in edible oil processing solutions and equipment in China, we provide complete plant solutions for oilseeds pretreatment, solvent extraction, refining and deep processing. More than 20 years’ experience, we are committed to optimizing technology processes, engineer design, project management, installation and training, help customer build the oil mill over the world. When you plan to build an vegetable oil processing plant, please contact us today to get the quote.

Email: company@dingmachinery.com, whatsapp: +86-159 3716 3029.

Email: company@dingmachinery.com, whatsapp: +86-159 3716 3029.

Related Products

-

Palm Oil Fractionation EquipmentPalm oil fractionation equipment separate palm oil into soft fat, hard fat and intermediates by controlling the crystallization point. The melting point of hard fat is 50°C and that of soft fat is 24°C.learn MORE

Palm Oil Fractionation EquipmentPalm oil fractionation equipment separate palm oil into soft fat, hard fat and intermediates by controlling the crystallization point. The melting point of hard fat is 50°C and that of soft fat is 24°C.learn MORE -

Sunflower Oil Dewaxing EquipmentSunflower oil is a kind of high-quality edible oil. it is rich essential fatty acids for the human body, unsaturated fatty acids up to 85 to 90 percent, and the content of linoleic acid is 65%, which has high nutritional value.learn MORE

Sunflower Oil Dewaxing EquipmentSunflower oil is a kind of high-quality edible oil. it is rich essential fatty acids for the human body, unsaturated fatty acids up to 85 to 90 percent, and the content of linoleic acid is 65%, which has high nutritional value.learn MORE -

Rice Bran Oil Winterizing EquipmentThe wax in edible oil is mainly formed by the reaction of higher fatty alcohols and higher fatty acids, in addition to some higher free fatty alcohols, fatty acids and hydrocarbons.learn MORE

Rice Bran Oil Winterizing EquipmentThe wax in edible oil is mainly formed by the reaction of higher fatty alcohols and higher fatty acids, in addition to some higher free fatty alcohols, fatty acids and hydrocarbons.learn MORE