50-500T Crude oil refining equipment

Zhengzhou Dingsheng Machine Manufacturing Co., Ltd has been engaged in the oil machinery manufacturing industry for more than 20 years. Considering the economic and practicality of the refining workshop, we recommend that customers use full continuous refining equipment for crude oil refining more than 50TPD.

Share With:

Product Description

The main features of the full continuous refining equipment are the high degree of automation, good quality of the finished oil. It is mainly used for pre-pressing-extraction and it can be used for the refining of rapeseed oil, cottonseed oil, peanut oil, linseed oil, rice bran oil, sunflower oil and other vegetable oils, and animal fats such as lard, tallow, and mutton oil produced by the one-time extraction process.

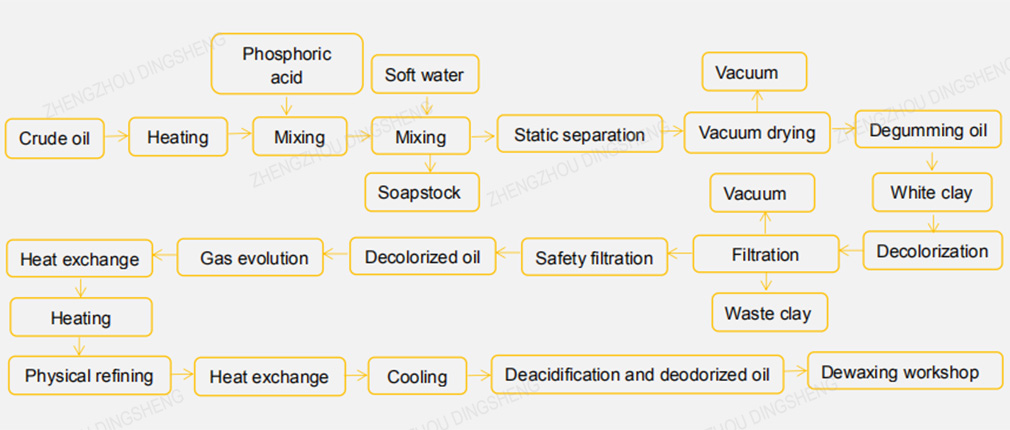

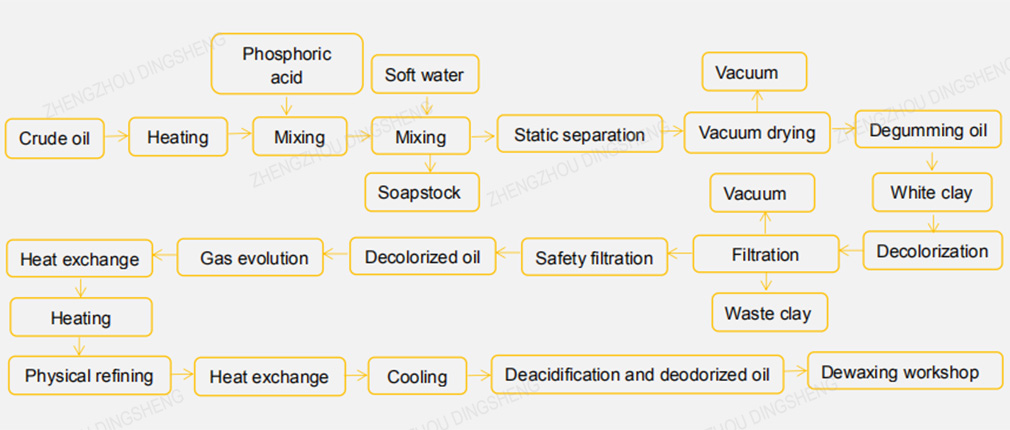

Technology Process

Fully continuous refining equipment can complete hydration, alkali refining, water washing, decolorization, and deodorization process operations, and adopts electronic metering, high-speed centrifuge desoaping, vacuum (continuous) drying and other excellent technologies. The main equipment of the full continuous refining workshop: centrifuge, decolorization tower, deodorization tower, leaf filter, four-stage steam jet pump, water jet pump.

Features

1

Crude oil degumming and alkali refining process: continuous alkali refining shortens the contact time of grease and lye, reduces grease saponification, lowers consumption, and improves efficiency;

2

Crude oil decolorization process: The decolorization adopts the process of premixing and steam agitation decolorization to improve the decolorization efficiency and save the amount of white clay; the negative pressure state avoids the contact of oxygen in the air with hot oil, guarantees the oil quality, and inhibits the acid value from rising and reducing POV.

3

Physical deacidification and deodorization process: physical refining adopts a new type of continuous deacidification and deodorization, which is suitable for the deacidification and deodorization of vegetable oils with high acid value and low colloidal content. It has strong deacidification ability, good thermal decolorization effect, better refining rate and good oil quality, etc.

4

Automatic control system: Automatic control is applied in the refining workshop. The computer can control the production of the whole workshop, and can monitor the operation status of each equipment. The whole workshop can be completed by one person, and the production management is efficient.

Edible Oil Processing With Dingsheng Machine

Dingsheng Machine is a leading manufacturer specializing in edible oil processing solutions and equipment in China, we provide complete plant solutions for oilseeds pretreatment, solvent extraction, refining and deep processing. More than 20 years’ experience, we are committed to optimizing technology processes, engineer design, project management, installation and training, help customer build the oil mill over the world. When you plan to build an vegetable oil processing plant, please contact us today to get the quote.

Email: company@dingmachinery.com, whatsapp: +86-159 3716 3029.

Email: company@dingmachinery.com, whatsapp: +86-159 3716 3029.

Related Products

-

Fish oil refining equipmentDingsheng Machine provides fish oil refining solutions, deguming, deacidification, winterization and deodorization production line, when you have a project plan for the fish oil processing plant, please contact us soon.learn MORE

Fish oil refining equipmentDingsheng Machine provides fish oil refining solutions, deguming, deacidification, winterization and deodorization production line, when you have a project plan for the fish oil processing plant, please contact us soon.learn MORE -

.jpg) Animal fat refining equipmentDingsheng Machine is a leading manufacturer for animal fat extraction and refining solutions and equipment in China. We provide professional technology and solutions, whether you specialize in fats from land-based animals such as cows, pigs or chickens, or work in the production of fish oils. Our comprehensive range of products helps you to increase yield while meeting highest product quality and minimum product loss. When you have a project plan for the animal fat processing plant, please contact us soon.learn MORE

Animal fat refining equipmentDingsheng Machine is a leading manufacturer for animal fat extraction and refining solutions and equipment in China. We provide professional technology and solutions, whether you specialize in fats from land-based animals such as cows, pigs or chickens, or work in the production of fish oils. Our comprehensive range of products helps you to increase yield while meeting highest product quality and minimum product loss. When you have a project plan for the animal fat processing plant, please contact us soon.learn MORE -

Palm oil refining equipmentDingsheng Machine provides palm oil refining solutions, batch refining (1-30 tons per day), continuous refining process, semi-continuous refining process, small palm oil refining production line equipment for degumming, deacidification, decolorization, deodorization and fractionation.learn MORE

Palm oil refining equipmentDingsheng Machine provides palm oil refining solutions, batch refining (1-30 tons per day), continuous refining process, semi-continuous refining process, small palm oil refining production line equipment for degumming, deacidification, decolorization, deodorization and fractionation.learn MORE -

1-10T Crude oil refining equipmentThe refining process of edible vegetable oils can be divided into general edible oil refining, High grade edible oil refining and special oil refining.learn MORE

1-10T Crude oil refining equipmentThe refining process of edible vegetable oils can be divided into general edible oil refining, High grade edible oil refining and special oil refining.learn MORE -

20-30T Crude oil refining equipmentIntroduction: The unrefined vegetable oil obtained by pressing or leaching is called crude oil. The crude oil obtained by mechanically squeezing the oil after magnetic separation, cleaning, crushing, flaking, steam-cooking is called machine-pressed crude oil. The crude oil obtained by pretreatment of the oil by solvent leaching and other methods is called leaching crude oil. After the machine-pressed and leached crude oil is refined, the finished oil can be directly put on the market for consumption.learn MORE

20-30T Crude oil refining equipmentIntroduction: The unrefined vegetable oil obtained by pressing or leaching is called crude oil. The crude oil obtained by mechanically squeezing the oil after magnetic separation, cleaning, crushing, flaking, steam-cooking is called machine-pressed crude oil. The crude oil obtained by pretreatment of the oil by solvent leaching and other methods is called leaching crude oil. After the machine-pressed and leached crude oil is refined, the finished oil can be directly put on the market for consumption.learn MORE -

30-50T Crude oil refining equipmentZhengzhou Dingsheng Machine Manufacturing Co., Ltd has been engaged in the oil machinery manufacturing industry for more than 20 years. Considering the economic and practicality of the refining workshop, we recommend that customers use full continuous refining equipment for crude oil refining more than 50TPD.learn MORE

30-50T Crude oil refining equipmentZhengzhou Dingsheng Machine Manufacturing Co., Ltd has been engaged in the oil machinery manufacturing industry for more than 20 years. Considering the economic and practicality of the refining workshop, we recommend that customers use full continuous refining equipment for crude oil refining more than 50TPD.learn MORE -

1-10T Crude oil refining equipmentThe refining process of edible vegetable oils can be divided into general edible oil refining, High grade edible oil refining and special oil refining.learn MORE

1-10T Crude oil refining equipmentThe refining process of edible vegetable oils can be divided into general edible oil refining, High grade edible oil refining and special oil refining.learn MORE